Laser cutting acrylic is the leading method for producing acrylic products due to its widespread popularity. This technique significantly enhances production efficiency, reduces costs, and minimizes material waste. Notably, laser cutting enables the creation of products with diverse shapes, intricate designs, and exceptional precision.

Compared to other plastic sheet materials, acrylic stands out as the ideal choice for laser cutting. Its good edge quality after laser processing boasts smooth textures without any discoloration or fading concerns.

Moreover, our services extend beyond laser cutting. We provide a comprehensive range of options. It includes laser engraving, marking, screen printing, UV printing, bending, drilling, tapping, and CNC machining specifically designed for acrylic materials.

Please browse through our impressive collection of laser cutting acrylic samples, showcasing a wide range of products. Our expertise includes acrylic sheet cutting, precise cutting of plexiglass thick plates, intricate acrylic decorations, single-line engraved acrylic pieces, deep engraved acrylic pieces, UV printed acrylic pieces, bending pieces, gluing pieces, and much more. These samples demonstrate the versatility and high-quality craftsmanship we bring to each project.

Laser cutting acrylic has already showed its extraordinary excellence in various industries, including craft gifts, advertising signs, displays, furniture, and home decoration. Acrylic creates complex designs and shapes through a highly accurate and efficient laser cutting process. It has some unique characteristics that other plastic sheet materials do not have. Acrylic products processed by laser can improve your project and aesthetic quality.

Our state-of-the-art, high-power laser cutting machine guarantees the utmost precision and accuracy when working with acrylic products. The laser beam is incredibly precise, resulting in a cutting seam of approximately 0.1mm for acrylic materials up to 3mm thick. This exceptional level of precision ensures that the final part perfectly matches your original design, delivering the best finished products of the high quality.

we can also achieve precise positioning and one-time shaping through fill engraving, accommodating both small and large engraved areas. Additionally, laser cutting provides a flame-polishing-like effect, resulting in glossy and smooth edges, enhancing the overall cleanliness and aesthetics of the acrylic pieces.

Our acrylic sheets boast outstanding quality in terms of color, smoothness, and transparency. With laser cutting, the resulting edges are smooth and flat, maintaining color consistency without any fading. When cutting plexiglass or colored transparent acrylic sheets, the edges not only retain smoothness and flatness but also offer exceptional transparency. In general, The acrylic products can be obtained without the need for secondary polishing. For instance, when working with 8mm-10mm plexiglass, we can adjust the power and speed of the laser cutting machine to achieve the desired effect, ensuring wonderful finish and transparency.

With the advantages of acrylic and laser cutting, these two things can integrate seamlessly to manufacture a wide array of products for both industrial production and daily life.

In the medical equipment industry, acrylic’s excellent chemical stability makes it a suitable material for producing matching components for various medical devices. For instance, it can be employed to create supports for test tubes or petri dishes, as well as panels for certain medical equipment.

Optical-grade acrylic sheets play a crucial role in the realm of optical instruments and equipment. Through laser cutting, we can get fabricate lenses, projection plates, and other optical components with optical acrylic materials, including double-sided transparent acrylic plates and translucent acrylic plates.

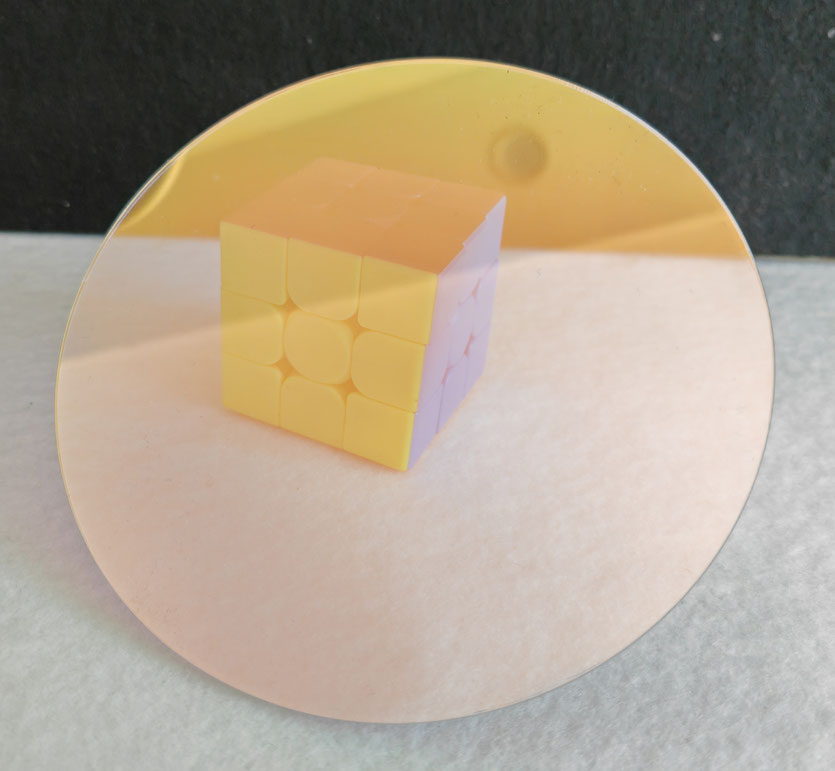

Unlike other plastic materials, acrylic offers a rich variety. Simply based on color, it includes solid color, colored transparent, fluorescent transparent, and iridescent acrylic, etc. These vibrant options enable the creation of limitless possibilities for home decoration, craft jewelry, cultural gifts, and other applications. This diverse selection empowers designers and product developers to cater to a wide range of consumer needs.

For example, designers can utilize acrylic laser cutting to produce jewelry, hangings, wall decorations, and an assortment of products in various shapes, sizes, and colors.

Moreover, acrylic can be used to craft commemorative refrigerator magnets, attractive wall clocks, and LED lighting displays depicting natural scenery.

Beyond the aforementioned applications, laser-processed acrylics find utility in the advertising and decoration industry, packaging industry, as well as the mechanical, electrical, and new energy sectors.

In terms of variety, acrylic offers a much wider range of options compared to other plastic panels. From a production process perspective, acrylic can be divided into two main types: cast acrylic and extruded acrylic sheet. Cast acrylic boasts a rich color palette, offering a wide range of color choices, and is well-suited for decorative products. While extruded acrylic sheets have a flat and uniform thickness, making them more suitable for processing assembled products like acrylic boxes and display shelves.

Acrylic can also be categorized based on light transmittance, including transparent acrylic (also known as plexiglass), translucent acrylic, and solid color acrylic. Transparent acrylic further includes color transparent and fluorescent transparent types.

Furthermore, acrylic is also classified based on function and use, encompassing ordinary acrylic sheets, anti-scratch sheets, anti-ultraviolet sheets, optical plates, and other types.

As the surface treatment options to choose sheets, they include single-sided frosted sheets, double-sided frosted sheets, and bright sheets. Additionally, acrylic can get a coating to produce mirror plates, dazzling acrylic plates, radium film plates, and more.

When it comes to color variations, there is a wide spectrum to choose from, including white, black, red, yellow, blue, green, pink, and many others. We maintain stock of commonly used colors and thicknesses to provide customers with laser cutting services. For other types, they are readily available in the market. For specific color and type details, please refer to the color card.

When it comes to engraving acrylic, common laser cutting machines are not ideal for mass marking processing due to their slow speed, limited accuracy, and high cost. To address these challenges and enhance the efficiency of acrylic engraving, we offer a specialized carbon dioxide laser marking system. This system is designed specifically for professional acrylic material marking, delivering fast and highly accurate results at a significantly lower cost compared to laser cutting machines. It is an excellent choice for mass marking processing.

Our process involves precise positioning of the acrylic parts, followed by single line marking, fill engraving, and deep engraving. The resulting patterns or text are exceptionally clear and nice, capturing even the smallest details with precision and clarity.

In addition to laser engraving, we also offer UV color printing services for acrylic products. With three different models and brands of UV printers, we can accommodate both small batch customization and high-volume production. Acrylic sheets provide an excellent substrate for UV color printing, and we specialize in UV color printing services with clear and white acrylic materials. Our prints boast vibrant, long-lasting colors that do not fade over time. This printing technology elevates acrylic products, adding a touch of sophistication and a wide range of color options for designers.

Beyond engraving and printing, we provide a range of other acrylic processing services, including bending, drilling, tapping, backgluing, and screen printing. These additional technologies ensure that your customized products are perfectly crafted to meet your unique specifications and requirements.

We take great pride in offering top-notch acrylic laser cutting services that are sure to exceed your expectations. When it comes to precise laser cutting of acrylic materials, we utilize the latest technology, including CNC software and CAD files, to ensure consistent quality in our cut products while eliminating any potential human errors. Moreover, our highly automated and advanced laser cutting machines guarantee reliable high-quality products at competitive prices, It is often below cost expectations from customers. At the same time, our services to customer satisfaction sets us apart from the competition, making us the ideal choice for all your acrylic laser cutting needs.

Quote prices within 24 HR

Call us: +86-151-76427816

email: vipur@foxmail.com

Quote prices within 24 HR

Call us: +86-151-76427816

email: vipur@foxmail.com